Submersible cages trialed at second site for Nippon Steel Engineering’s offshore aquaculture system

When Nippon Steel Engineering Co., Ltd. set out to design a new offshore aquaculture system, it was able to draw on its existing in-house expertise.

The company, which was formed out of a 2012 merger between Nippon Steel Corp. and Sumitomo Metal Industries, Ltd., branched into aquaculture with the long-term goal of creating a successful large-scale offshore aquaculture system. It began its effort in 2016 by joining forces with Yumigahama Suisan Co. Ltd., a salmon farming operation owned by the Nissui group, with which it began experimental project in Sakaiminato City, Tottori Prefecture, Japan.

While relying on Yumigahama Suisan’s expertise in coho salmon farming, Nippon Steel Engineering added several features into the operation’s design that it had developed through its other business entities. For example, the system employs a platform for storing feed that is similar to those the company built for the offshore oil and gas industries. It also has an underwater piping system that uses a blower to deliver feed to cages, which resembles those the company uses to move pulverized coal in its steel mills.

The Sakaiminato City site has a platform of approximately 300 square meters in 15-meter-deep water on which two feed silos of 25 square meter capacity are fixed. The feed silos need to be refilled only about once a week, and feeding can be done by remote control via the piped system that extends 150 to 300 meters, so that there is no need to sail in rough weather. But the cages are of the normal floating type used by Yumigahama Suisan, and the operation has put in place the proprietary “Aqualingual” feeding system developed by Nissui. In this system, the salmon can voluntarily feed when hungry by pulling on artificial food.

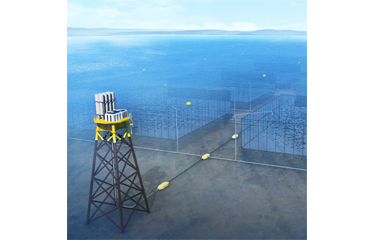

Now, according to a 2020 technical report on the project, Nippon Steel Engineering has expanded further into aquaculture with a second demonstration site in Owase City, Mie Prefecture, in cooperation with Owase Bussan Co., Ltd. and the Mie Outer Bay Fisheries Cooperative Group. The farm is trailing large submersible cages located in water approximately 60 meters deep. The cages are used for yellowtail, and the first experimental batch was farmed from March of 2017 through March of 2018.

The larger-scale, open-water aquaculture system has three major parts: optimized production management system software that improves the feed-conversion ratio, automated feeding system hardware that saves labor, and larger cages that can hold more fish and withstand rough weather.

The submersible cages are designed to make the cages more able to withstand surface turbulence caused by harsh weather, as when submerged, the cages are not lifted and dropped with every wave. The system is designed to withstand ocean waves of seven meters and tidal currents of up to two knots, and the design has thus far been successful, having survived several severe typhoons that have hit Japan recently.

Another novel aspect of the farm is the feed silos employed, which are located onshore and sent via a long pipe into the system. The system has shown that feed can be delivered to the silos conveniently by truck. Its success shows the company has demonstrated two viable options for its system, enabling those who employ it to choose whether to use a platform-based or land-based feed system.

Yoshiko Fugane, an inside sales representative in Nippon Steel Engineering’s aquaculture system business department, told SeafoodSource the system at Owase City does not use Aqualingual (which has a unit that sits above each cage and is not meant to be submerged), but instead observes fish with underwater cameras mounted in the cages, and combines image analysis with environmental conditions to estimate their hunger level.

A variety of sensors monitor conditions including water temperature, salinity, weather conditions, tides, wind speed, direction, and carbon dioxide level, and then artificial intelligence is used to analyze these factors to determine the correct amount of feed to be deployed. Reducing wasted feed is the key to lowering production costs, as it generally accounts for most of the expense in fish farming, Fugane said.

While embracing innovation and creatively redeploying existing technology from other sectors, Nippon Steel Engineering still faces another big hurdle: finding interested buyers.

Interest in offshore aquaculture has existed worldwide for years, but the global regulatory and licensing framework has been developing slowly. While offshore finfish projects exist in Norway, China, Panama, Mexico, Turkey, and Southeast Asia, current global production is minimal, according to a 2018 report by the The David and Lucile Packard Foundation.

The likeliest buyers are located in Norway and China, which together have seen between USD 1.5 billion and USD 2 billion (EUR 1.2 million and EUR 1.7 billion) invested in offshore aquaculture in waters under their control in the past four years. Between these two, China is probably the best bet, as Norway has a much more developed aquaculture industry. While China has jumped into the game with the recent launch of several massive offshore rigs with production capacities of one to two million fish, it appears eager to learn more about what works in the sector and might be interested in the advancements being offered by Nippon Steel.

Photo courtesy of Nippon Steel Engineering

Share